Products

Contact Us

Telephone:+86 0391-8987988

Mobile:+8613598529809

Mailbox:liyao7979@163.com

Address: North of the next phase of Chengcun, Hongchang Sub-district Office, Boai County, Jiaozuo City, Henan Province

The high-voltage pulse generator fully meets the requirements of DL/T846-2016 "General Technical Conditions for High Voltage Test Equipment" and DL/T474-2017 "Guidelines for the Implementation of Field Insulation Tests". It is mainly used for impulse discharge and withstand voltage tests during low and high voltage cable fault tests.

This device integrates a DC high voltage source, energy storage capacitor, discharge ball device, automatic discharge device, and voltage level switching device into a cart-type high-end experimental instrument. This equipment completely solves the problems of ease of use, portability, safety and reliability of traditional experimental devices.

This instrument uses high-precision, high-stability dedicated high-voltage electronic components and high-frequency high-voltage technology to make its overall structure simple. In order to retain people's original habit of using transformers and operating boxes to generate DC high voltage, this pulse generator adopts a humanized design operation mode and integrates a micro-reliable circuit design. It is safe, reliable, and visually intuitive. It truly achieves the effect of being indestructible by impact, and also has automatic timing impact, manual impact and withstand voltage functions. It is currently the most humane cart-type DC impact high-voltage equipment in China. It is an ideal product for power cable fault detection.

The cable fault tester uses an industrial-grade 10.1-inch touch-integrated computer with a simple operating software interface to achieve human-computer interactive testing. It uses industrial-grade integrated circuits and devices, and has a built-in large-capacity lithium-ion battery, which is stable, reliable, and easy to use.

This cable fault tester is a special instrument for measuring and analyzing the status and fault distance of power cables. This cable fault tester combines modern electronic technology and computer technology to achieve signal filtering, acquisition, data processing, graphic display, and graphic analysis to complete cable speed measurement, cable length testing, and cable fault distance testing.

This cable fault tester is suitable for low-resistance, short-circuit, open-circuit and broken-wire faults of power cables, high-frequency coaxial cables, street light cables, and underground wires of various materials with different cross-sections and different media, as well as high-resistance leakage and high-resistance flashover faults. The technical parameters comply with the requirements of "GB/T 18268.1 Anti-interference requirements for test equipment for industrial sites", "DL ∕ T 849.1-2019 General technical conditions for special testers for power equipment Part 1: Cable fault flash detector", and "JJF1042-2020 Cable fault tester calibration specification".

The circuit fault tester is equipped with an industrial-grade 10.1-inch touchscreen all-in-one computer and features a simple operation software interface to achieve human-machine interactive testing. It utilizes industrial-grade integrated circuits and components, with a built-in high-capacity lithium-ion battery, ensuring stable reliability and convenient use.

This circuit fault tester is a specialized instrument for measuring and analyzing the status and fault distance of power cables. By integrating modern electronic technology with computer technology, it realizes functions such as signal filtering, acquisition, data processing, graphical display, and graphical analysis to complete tests including cable velocity measurement, cable length testing, and cable fault distance measurement.

This device is applicable to various power cables (of different cross-sections and dielectric materials), high-frequency coaxial cables, street lamp cables, and underground wires. It can test low-resistance, short-circuit, open-circuit, and broken-wire faults, as well as high-resistance leakage faults and high-resistance flashover faults. Its technical parameters comply with the requirements of the following standards: GB/T 18268.1 Requirements for the Interference Immunity of Test Equipment for Industrial Premises, DL/T 849.1-2019 General Technical Conditions for Specialized Testers for Electrical Equipment Part 1: Cable Fault Flash Detectors, and JJF 1042-2020 Calibration Specification for Circuit Fault Testers.

Function:

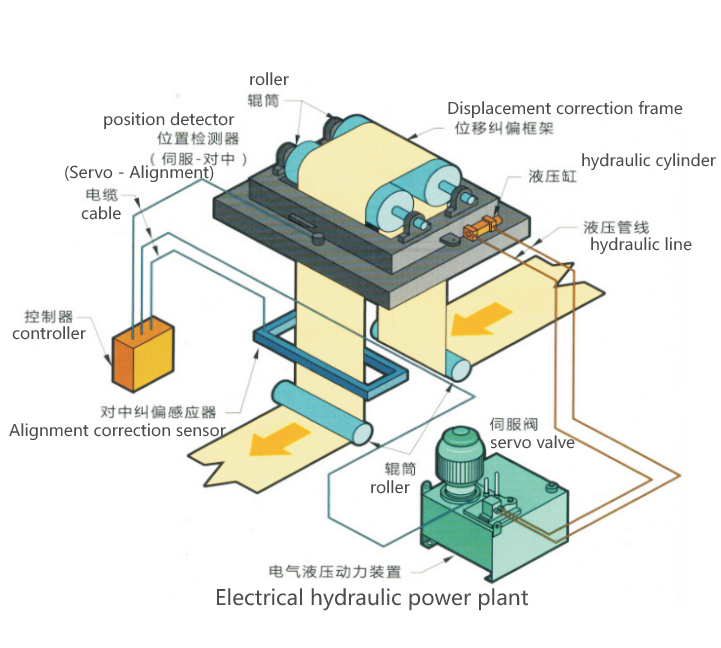

The deviation correction of the middle roll depends on the deflection of the correction frame with fixed deviation center around its center, which causes the strip to move sideways or sideways. In order to obtain the best results, it should be ensured that the inlet and outlet strips are perpendicular to the motion plane of the correction frame, and the detection device is arranged at the exit of the correction roll as close as possible to the correction frame.

The pulse energy storage capacitor adopts imported film and non-inductive winding structure. It has good self-healing and explosion-proof performance. It has the characteristics of reliable structure, no leakage, no pollution, moisture-proof, fire-proof, long life, small size and light weight.

The high-voltage pulse generator fully meets the requirements of DL/T846-2016 "General Technical Conditions for High Voltage Test Equipment" and DL/T474-2017 "Guidelines for the Implementation of Field Insulation Tests". It is mainly used for impact discharge during low-voltage cable fault testing.

This device integrates DC high-voltage source, energy storage capacitor, discharge ball gap, etc. This equipment completely replaces the traditional test transformer, operation box and pulse energy storage capacitor weighing hundreds of kilograms (generally a set of 5kVA transformers weighs more than 60 kilograms, control boxes weigh more than 30 kilograms, and pulse energy storage capacitors weigh more than 20 kilograms).

This power supply uses high-precision, high-stability dedicated high-voltage electronic components and high-frequency high-voltage technology to make the whole machine simple in structure and ultra-light in weight. In order to retain people's original habit of using transformers and operation boxes to generate DC high voltage, this instrument adopts a humanized design operation mode, which is safe and reliable. It truly achieves the effect of not being damaged by impact, and the high voltage can also work normally when it is short-circuited to the ground. It is currently the lightest and most humane portable DC impact high-voltage equipment in China. It is our dream product for power cable fault detection.

Uncoiling Alignment:Open book alignment correction

Principle:

Uncoiling alignment alignment is based on two detection sensors to detect the strip edge position, the edge position according to the pre-set position (correction zero) error. The detection sensor converts the error into an electrical signal and input it to the correction servo system. The correction controller compares the signal with the correction zero signal and outputs a corresponding correction signal to the servo valve, which converts the electrical signal into hydraulic flow and drives the hydraulic cylinder to move the uncoiler in two directions until the strip is controlled on the pre-set center line

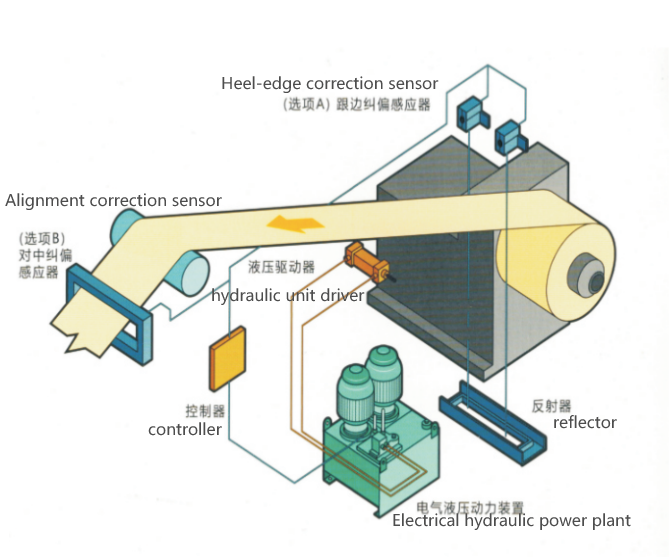

Edge Position Control:Take up the opposite side and correct the deviation

Principle:

The system monitors the edge of the steel belt according to the detection sensor, and the detection sensor converts the error into an electrical signal and inputs it to the correction servo system. The controller compares the signal with the correction zero signal and outputs a corresponding correction signal to the service valve. The servo valve converts the electrical signal into hydraulic flow rate and drives the hydraulic cylinder to push the winder to move in two directions. Until the strip is controlled on a pre-set edge line.

Product Features☆ The sampler integrates a flashover waveform collector and an adjustable discharge ball gap;☆ Mainly used for main insulation fault testing.Technical Parameters★ Withstand voltage: 120kVDC between the high-voltage terminal and the bottom shell of the instrument.★ Gap withstand voltage: greater than 0~110kVDC.★ Ground withstand voltage: 110kVDC between the high-voltage terminal and the ground terminal.★ Handle withstand voltage: greater than 70kVDC between the high-voltage terminal and the rotating handle.