Products

Contact Us

Telephone:+86 0391-8987988

Mobile:+8613598529809

Mailbox:liyao7979@163.com

Address: North of the next phase of Chengcun, Hongchang Sub-district Office, Boai County, Jiaozuo City, Henan Province

DK-HF Welding Seam Detector

Key words:

DK-HF welding seam detector

Key words:

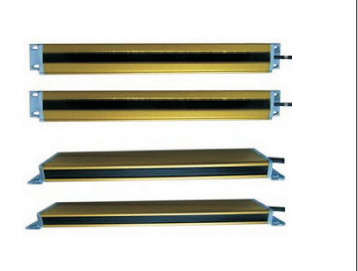

DK-HF Welding Seam Detector

Classification:

Product description

Overview:

DK-HF welding seam detector is mainly used for metallurgical sheet production line, through the detection of welding plate reserved holes to detect the purpose of welding, output a set of switching parameters for automatic control.

Principle:

This weld inspection is specially used for the inspection of welding reservation holes in the lead and tail joint parts of the plate. Leave a hole with a diameter of more than 15 at the weld position, and output a signal when the hole passes through the weld detector. The detection device consists of a group of transmitting and receiving signals, which are processed externally by signal processing amplifiers, and finally output a switch control signal.

Parameter:

1. Maximum speed of strip steel 300m/min

2. Minimum diameter of strip punching is 15mm

3. The system response time is 20ms

4. Working power supply AC220V±15%

5. Working environment temperature -30 ℃ ----+60℃

6. Detection range 200mm

Product inquiry